Preparing for a research cruise is a lot of work, largely because we tend to bring a lot of stuff (most of it even needed). Just how much stuff depends on several factors, mainly revolving around the project itself and how many days at sea are dedicated to that particular project. This summer’s cruise: it is just us! All the time we are at sea is dedicated to our project. That means that other than when we’re moving between our study sites, the winch is just sending the multi-core down and bringing the multi-core back up, and sending the multi-core down and bringing the multi-core back up. Our goal is to stop at 7 sites (locations representing different water depths, different sediment composition, and variable water characteristics).

A rough estimate is that we need 60 (successful) cores per site — that is truly a lot of mud! Fortunately, with the multi-corer we can, in theory, get 8-12 cores per deployment. Keep in mind however, just because the multi-corer goes down, does not mean that we’ll successfully recover sediments. As cool as the multi-core is, it still a finicky instrument that is largely being controlled by gravity and wire tension at distances of 2-5 km below the ship – we’re very happy if it works 70% of the time in open water (waves make everything harder!) Did I mention time? These deeper sites, let’s say the average depth of the ocean 4 km (or 4000 m), take at least an hour and a half, usually closer to 2 hours just for the multi-core to go down (typical speeds are between 30 and 50 meters per second for the cable to spool out). The good news is that gives us time after a successful deployment to process the batch of cores (or at least get a good start) before the next 12 are on deck! We need to have plenty of core tubes so we can re-deploy the multicore while we’re still processing the first batch of cores (and in case we break some — these tubes tend not to like rocks very much).

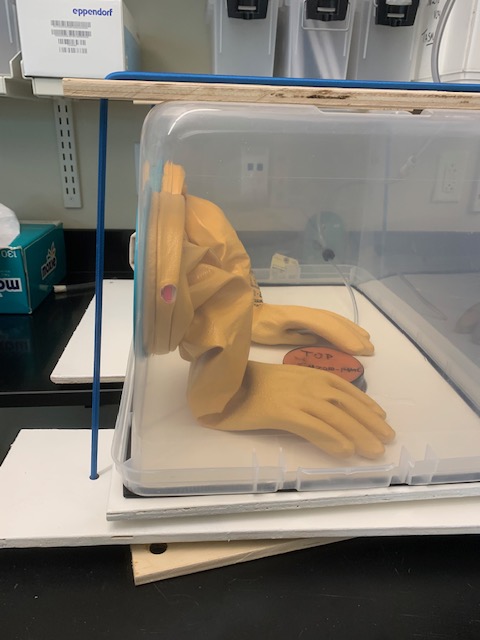

So what does 450 cores look like in terms of supplies to be able to sample that much sediment? Short answer: a lot. We’re bringing about 10 pallets of gear with us (mainly consumables like syringes and bottles and tape) to meet the ship in NYC and all our ‘bigger’ gear is meeting us there. We’ll have two ‘lab vans’ meet us at the ship, essentially shipping containers outfitted to be temperature controlled laboratory space that can be set on the deck of whatever research vessel they are needed on. The coring equipment including the corer and all the tubes, and the winch for the deployment of the corer, will also meet us at the wharf – as will our 50 (!!!) cylinders of compressed nitrogen gas (our samples are sensitive to oxygen so we have to be careful to not expose them to ambient air). On the other hand, the larger of the equipment coming with us and included in those 10 pallets is restricted to a couple of centrifuges, our glove boxes, a freeze dryer, some dehumidifiers, and a large sink.

Our main goal is pore water neodymium isotopes, so we have to be able to isolate the pore water from the sediments. And because we care about neodymium (and the other rare earth elements) we can’t use rhizons to do it — we have to section the core into centrifuge tubes, all in the globe box so we’re not exposing the sediments to additional oxygen from the ambient air. Then, once the tubes are sealed we can remove them from the box and spin them really really fast so the water comes out of the sediments and gathers at the top of the tube. We use each centrifuge tube once per trip, that’s a lot of centrifuge tubes, ~4000 to be exact. And syringes and filters to then pull off that water and filter it.

But we can’t tell the full story of sedimentary processes without describing other pore water and sediment characteristics. Some of these additional measurements can be collected the same way, but others need to be collected using rhizons. So we have rhizons as well, many many many rhizons. This also means we need to have core tubes pre-drilled so the rhizons can just punch through electrical tape to sample rather than having to cut the rigid plastic tube after its filled with sediment and potentially compromise the sample. In short, just making the list and then tracking the inventory as we order it is a huge task in and of itself. And it has to be right. Once you’re on the ship, you can’t just go to the store or order delivery if you forgot something. We have inventories on every box, all 10 pallets of them- and barely a week goes by we’re not opening a box to double check a count on this or that (for about the 100th time) just to make sure.

Then there is the cleaning. We’re looking for elements that occur naturally at very very low levels which means anything we’re going to touch the samples with have to be clean. Most of the time this involves a 24hr + soak in or filled with a weak acidic solution (combined with a series of rinses and soaks with very very clean water referred to as milliQ). For the centrifuge tubes, the inside has to be clean but the outside of the tube often is not- so instead of soaking the tubes in an acidic solution and risking contaminating the clean interior with stuff from the outside of the tube (when our goal is to make the interior even cleaner), we fill each tube with the weak acid and let it sit. Then they get rinsed with milliQ several times and are dried before being counted and packed. For the syringes, we separate the plungers to prevent air bubbles and then everything is submerged in an acid bath, soaked, rinsed, submerged in a milliQ bath, soaked, rinsed, and dried.

While the cleaning and packing progresses in the lab and inventories are built as we make piles of ‘cruise-ready’ action packers and totes in the warehouse we are busy coordinating and planning within the science party, with our coring team, and with the ship. With a largely green science party (most of our team has never been to sea) it is even more important than usual to set expectations and go over some of the basics before we even get to the ship. We need to figure out who will do what, make sure everyone is physically and mentally prepared to be on board, figure out room arrangements, and make sure everyone knows what they should bring. Then the coordination between our team, the ship, and the coring group is essential if the science is going to work- everyone needs to be on the same page and know who is doing what. Its always a chaotic lead up, but theres nothing quite like when it all comes together and the ship finally leaves the wharf.

“A smooth sea never made a skilled sailor.” — F. D. Roosevelt

I will never complain again when faced with sink full of dirty dishes.

LikeLike